Pilkington’s Tile and Pottery Co. Ltd.

Clifton Junction

Clifton Junction

Research and written content © Wallwork History

Images Salford Local History Library & Wallwork History

Images Salford Local History Library & Wallwork History

This page will mainly focus on the decorative pottery produced and the artists who created them at Pilkington's Tile & Pottery Co.

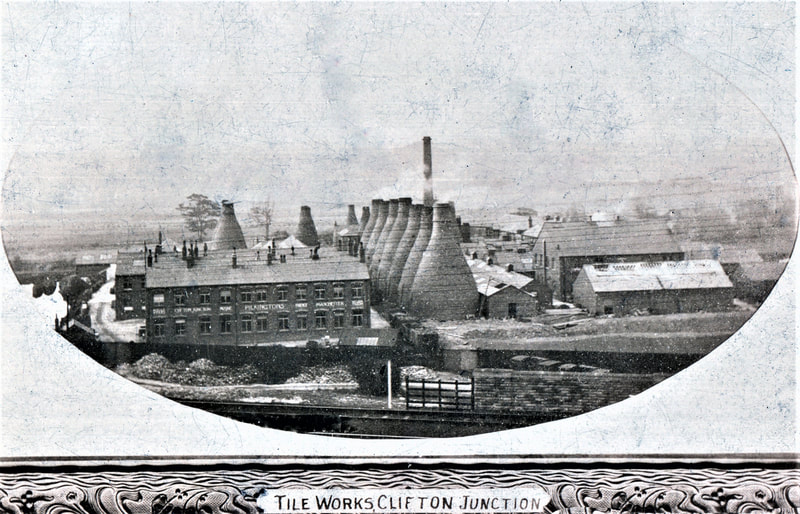

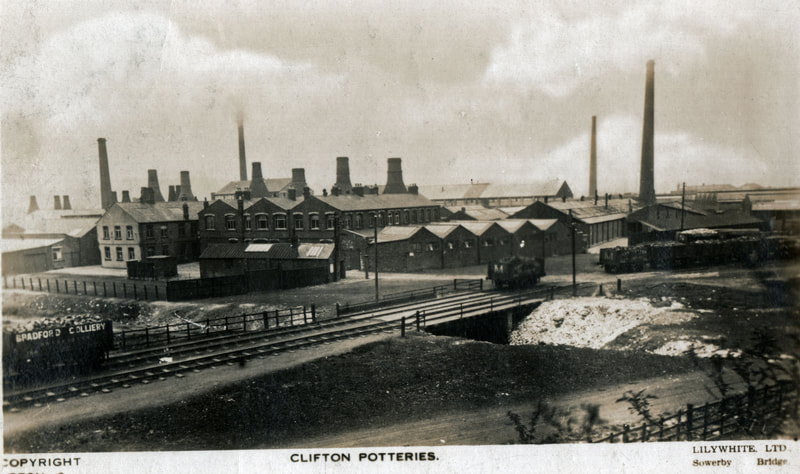

In 1889 The Clifton and Kersley Coal Company owned by the Pilkington brothers Alfred, Charles, Lawrence and Edward sank a couple of coal pit shafts next to the Pendleton fault.

The brothers were the sons of Richard Pilkington of Pilkington’s Glass.

It soon became clear that the pits would not produce coal as there was too much water and red Marl.

The Pilkington brothers decided to use to this marl to make glazed bricks, they were already making bricks in their nearby Billy Lane brick works.

There were several other brick works in the area, glazed bricks and tiles were used in buildings for decorative and sanitation purposes.

The brothers were the sons of Richard Pilkington of Pilkington’s Glass.

It soon became clear that the pits would not produce coal as there was too much water and red Marl.

The Pilkington brothers decided to use to this marl to make glazed bricks, they were already making bricks in their nearby Billy Lane brick works.

There were several other brick works in the area, glazed bricks and tiles were used in buildings for decorative and sanitation purposes.

Glazed bricks and tiles were used in buildings for decoration and sanitation purposes. For example Butchers shops, fishmongers, hospital etc. they created easy surfaces to wipe down and keep clean, as well as being decorative.

The Pilkington brothers asked William Burton a chemist working for Josiah Wedgewood & Co, to test the marl/clay and give his opinion on using it to make bricks.

William Burton suggested making tiles instead of glazed bricks, as at the time decorative tiles had become very fashionable and were in high demand.

Making tiles would also be more profitable for them.

The Pilkington brothers took William Burton’s advice and invited him to come and be the manager of their new modern built factory in Clifton.

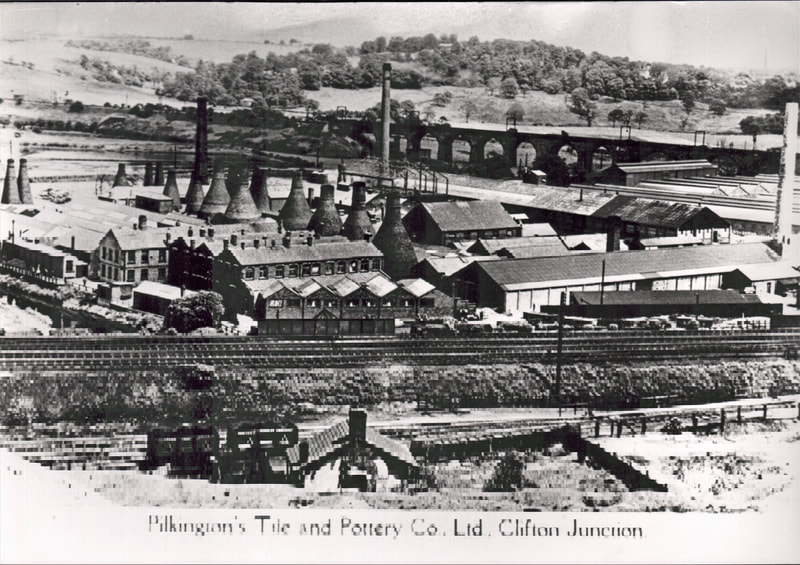

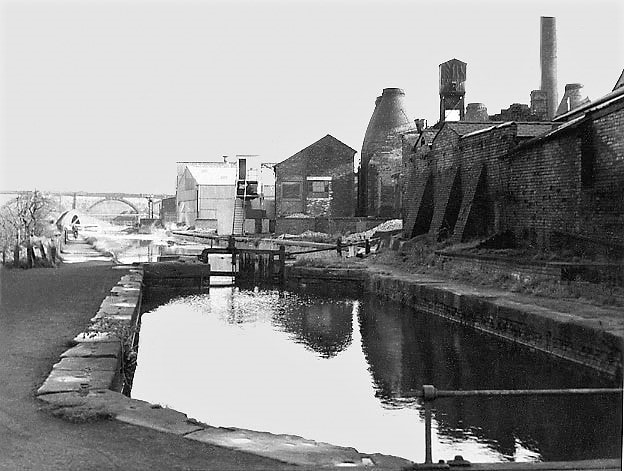

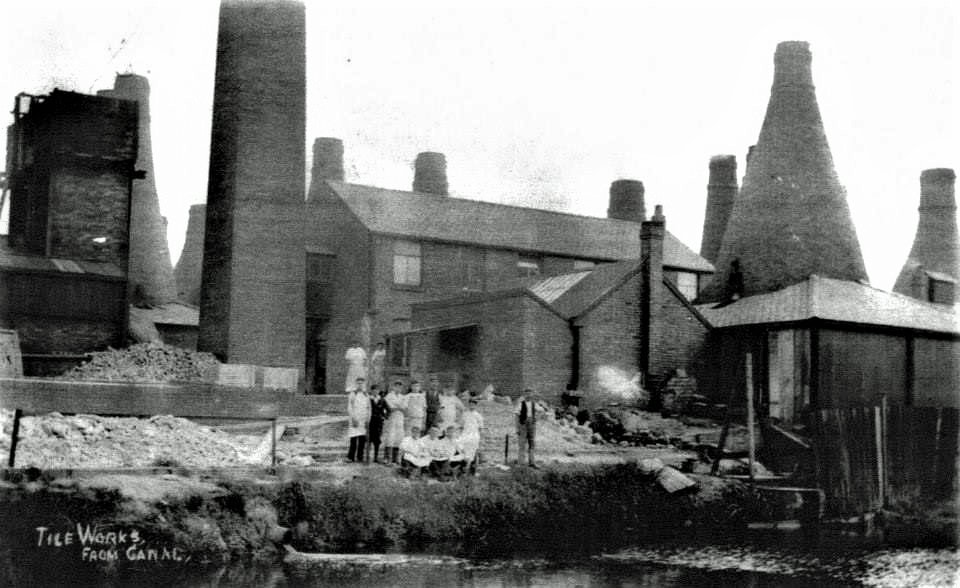

William Burton helped to design the factory, the site of which was chosen for its many advantages, it was next to the canal. Clifton railway station was close by and of course they had plenty of coal from the Wet Earth colliery.

William Burton suggested making tiles instead of glazed bricks, as at the time decorative tiles had become very fashionable and were in high demand.

Making tiles would also be more profitable for them.

The Pilkington brothers took William Burton’s advice and invited him to come and be the manager of their new modern built factory in Clifton.

William Burton helped to design the factory, the site of which was chosen for its many advantages, it was next to the canal. Clifton railway station was close by and of course they had plenty of coal from the Wet Earth colliery.

Although Pilkington’s Tile & Pottery Co. was owned by the Pilkington brothers. It was William Burton and his brother Joseph who established it and ran it.

Pilkington’s Tile & Pottery Co opened in 1892. One of the brothers Lawrence Pilkington took a keen interest in the arts and often visited the factory. The other brothers concentrated on managing the coal mines.

The company began tile making in 1893 they didn’t use the marl they found in the two coal pits, they closed them up and used the clay they had already been using to make bricks at their nearby brick works.

Pilkington’s Tile & Pottery Co opened in 1892. One of the brothers Lawrence Pilkington took a keen interest in the arts and often visited the factory. The other brothers concentrated on managing the coal mines.

The company began tile making in 1893 they didn’t use the marl they found in the two coal pits, they closed them up and used the clay they had already been using to make bricks at their nearby brick works.

The factory was designed for making tiles for walls, floors, fireplaces etc…

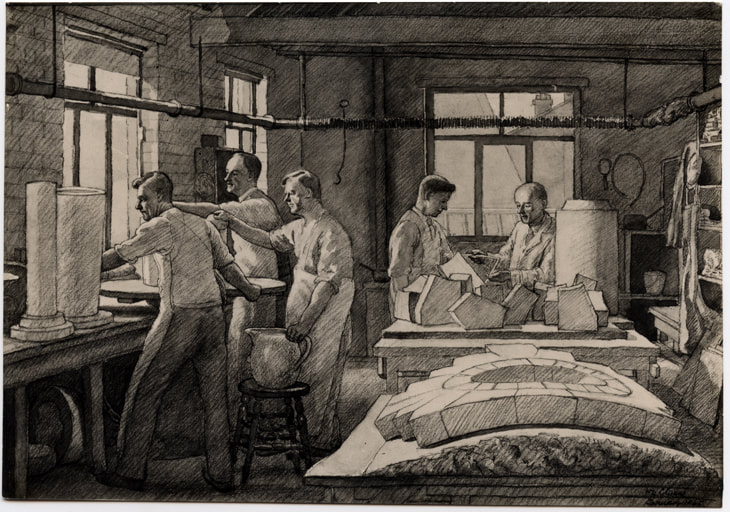

Tiles were made by using the clay dust compression process, the clay was dried and compressed then decorated and glazed.

Glaze is used on bricks/pottery and porcelain to give it a waterproof finish. The glaze ingredients melt and become like glass. Glazes can be transparent, opaque or coloured.

As well as using the clay from their brick works, they also used clays and stone brought from the south of England.

They had flint and other minerals imported.

These were brought in by train to Clifton Junction and also by barges along Fletchers canal, it was unloaded onto their own siding and stored on site.

Glaze is used on bricks/pottery and porcelain to give it a waterproof finish. The glaze ingredients melt and become like glass. Glazes can be transparent, opaque or coloured.

As well as using the clay from their brick works, they also used clays and stone brought from the south of England.

They had flint and other minerals imported.

These were brought in by train to Clifton Junction and also by barges along Fletchers canal, it was unloaded onto their own siding and stored on site.

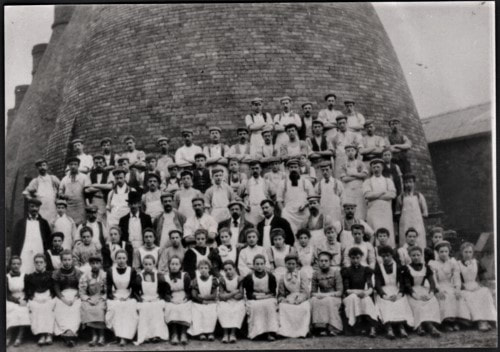

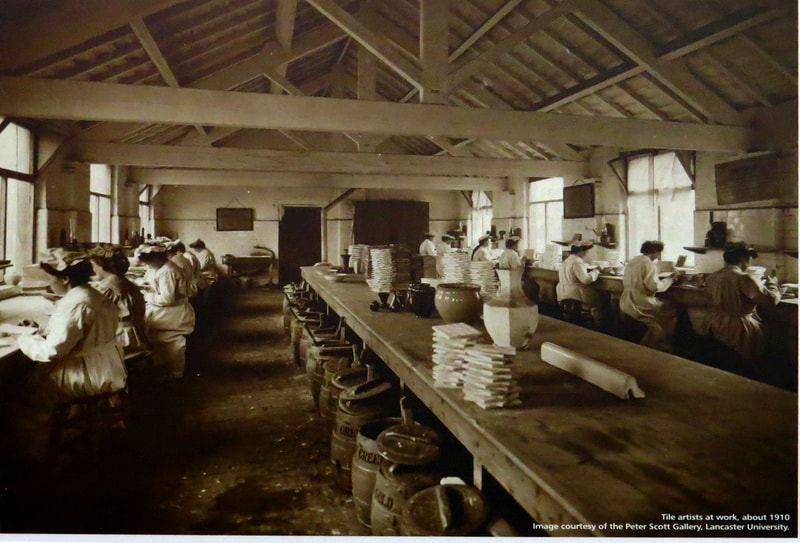

The opening of the factory enriched the area in many ways, it gave local people an opportunity to get out of the coal mines and cotton mills.

It was a new industry in the area and people were given the chance to be creative by making colourful pottery and tiles.

There was always full employment with favourable wages and many family members worked there together.

Given that William Burton was a chemist and scientist he provided his staff with a drink of milk each day, to reduce the effects of working with chemicals used in the glazes.

Lead, tin and salt were used in the glazes and he knew that calcium helped to prevent lead poising. He was thought to have been a caring father figure employer.

It was a new industry in the area and people were given the chance to be creative by making colourful pottery and tiles.

There was always full employment with favourable wages and many family members worked there together.

Given that William Burton was a chemist and scientist he provided his staff with a drink of milk each day, to reduce the effects of working with chemicals used in the glazes.

Lead, tin and salt were used in the glazes and he knew that calcium helped to prevent lead poising. He was thought to have been a caring father figure employer.

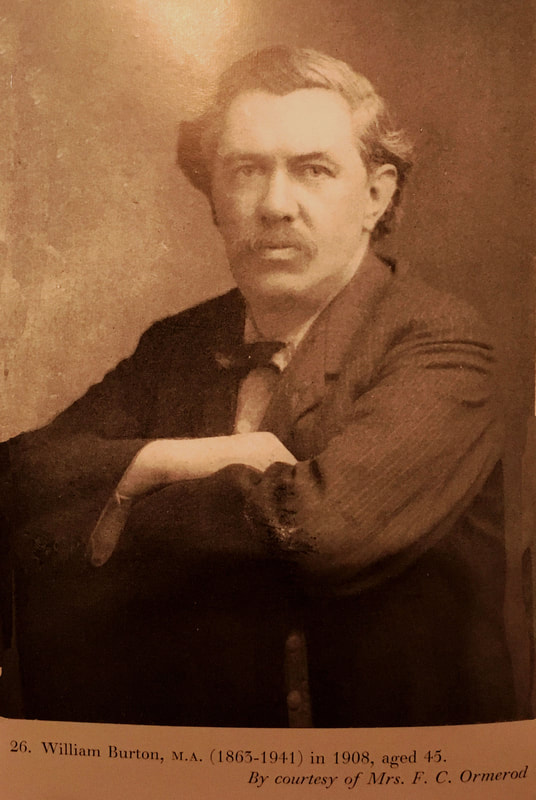

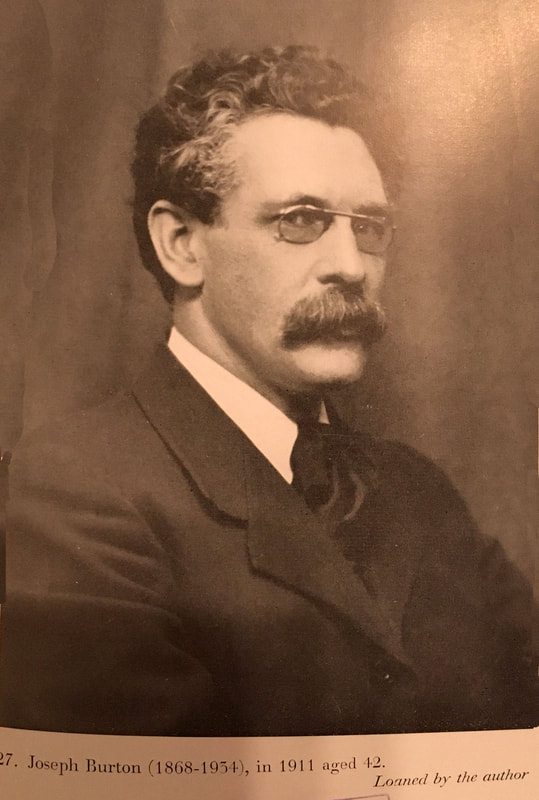

William Burton & Brother Joseph Burton

William Burton was born 1863 and Joseph his brother 1868 they were the sons of a grocer from Newton Heath.

William lived at The Hollies on Rake Lane near Clifton Junction, where he and his wife Eliza entertained many famous artists and influential people of the day, even Miss Sylvia Pankhurst who was a friend.

William Burton was born 1863 and Joseph his brother 1868 they were the sons of a grocer from Newton Heath.

William lived at The Hollies on Rake Lane near Clifton Junction, where he and his wife Eliza entertained many famous artists and influential people of the day, even Miss Sylvia Pankhurst who was a friend.

In 1897 the factory started to make pottery from moist clay stored in slabs on site, as well as making tiles.

They began by making buttons, hat pins and some vases made from moulds.

Before making and decorating their own pottery, they decorating some items of pottery sent from a long established pottery in Kirby Lonsdale.

This gave them the chance to practice some of their artistic skills.

They began by making buttons, hat pins and some vases made from moulds.

Before making and decorating their own pottery, they decorating some items of pottery sent from a long established pottery in Kirby Lonsdale.

This gave them the chance to practice some of their artistic skills.

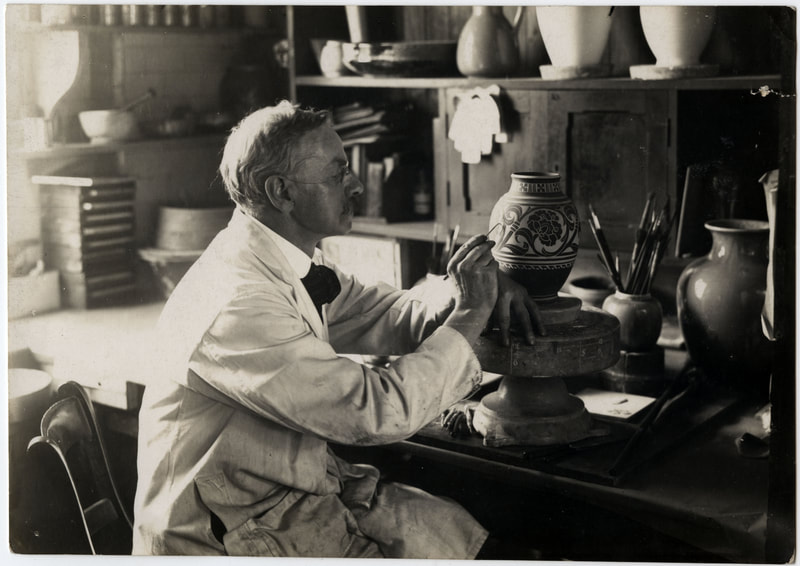

In 1903 they obtained a throwing wheel and the large scale manufacture of Lancastrian Pottery began.

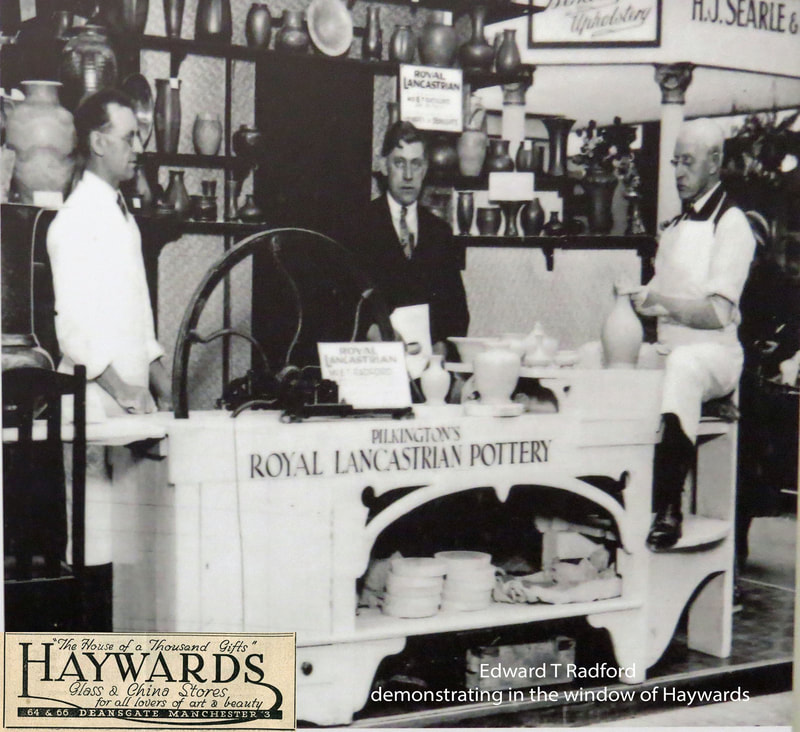

Edward .T. Radford

Edward .T. Radford joined Lancastrian Pottery in 1903, he handmade the pottery and remained working at Pilkington’s until his retirement in 1936 aged 76. He was known as one of the finest experienced throwers of his time.

You will see his mark E.T.R. on the base of the pots alongside the artist stamp or signature.

Edward .T. Radford

Edward .T. Radford joined Lancastrian Pottery in 1903, he handmade the pottery and remained working at Pilkington’s until his retirement in 1936 aged 76. He was known as one of the finest experienced throwers of his time.

You will see his mark E.T.R. on the base of the pots alongside the artist stamp or signature.

Each piece of pottery was thrown by the potter on a wheel and then hand painted and decorated by individual artists.

The pottery they made at Pilkington’s Lancastrian Pottery was of very good quality and no two pieces were the same.

All the artists painted tiles, but the majority of the pottery was painted by

Gordon Forsyth, Richard Joyce, Charles Cundall, William Mycock, Gwaldys Rodgers, & Annie Burton (niece of William the manager).

The pottery they made at Pilkington’s Lancastrian Pottery was of very good quality and no two pieces were the same.

All the artists painted tiles, but the majority of the pottery was painted by

Gordon Forsyth, Richard Joyce, Charles Cundall, William Mycock, Gwaldys Rodgers, & Annie Burton (niece of William the manager).

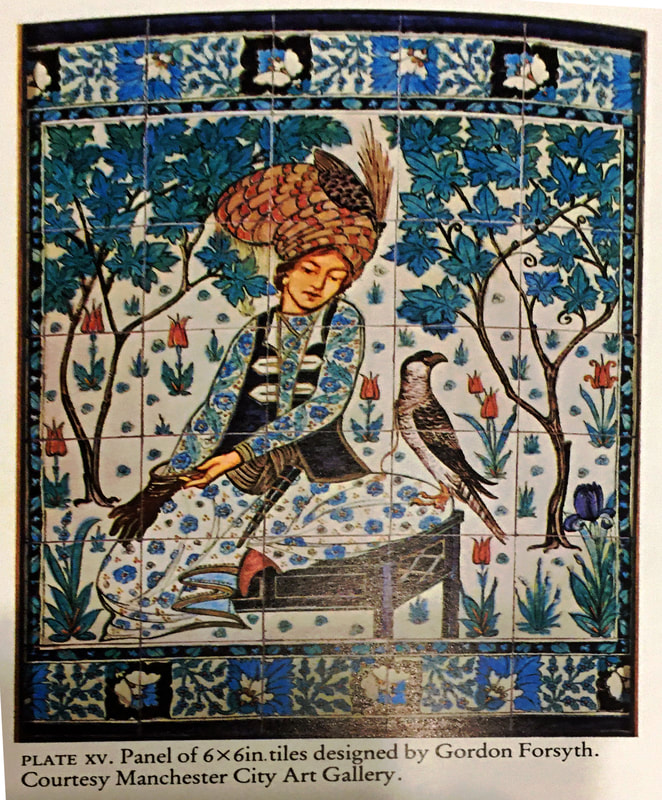

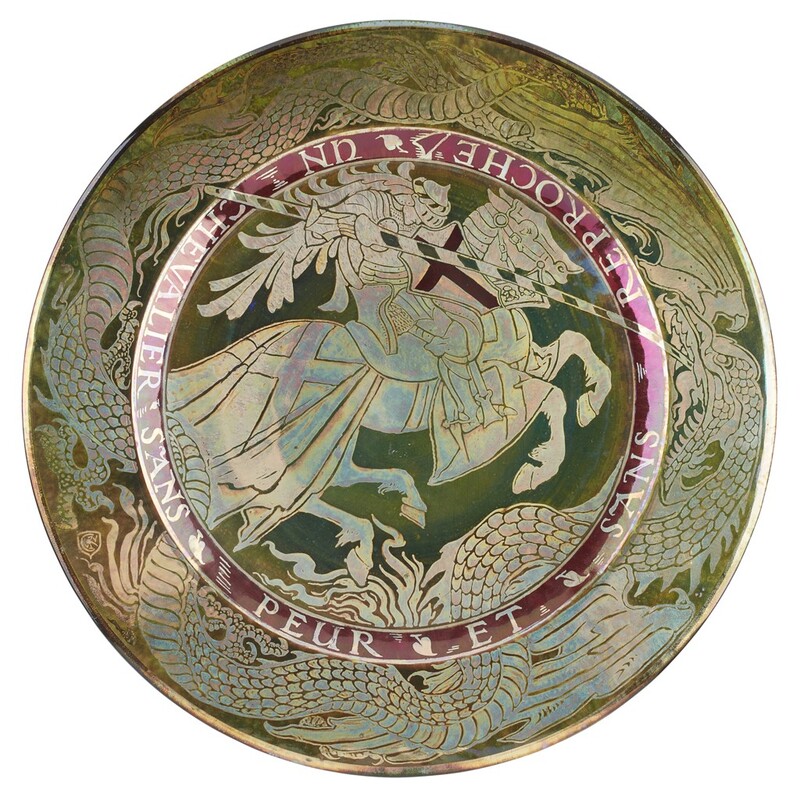

Gordon M. Forsyth

Gordon was born in 1879 and join Lancastrian Pottery in 1905 as the art director, he had previously been the art director of Minton pottery.

He produced many exciting designs for the lustre pottery which were made at Pilkington’s.

His designs were influenced by Persian, Spanish and Grecian designs, which can clearly be seen in his work.

He left in 1916 to do service in the Royal Flying corps and returned after the war in 1919 for a year leaving Pilkington’s in 1920.

He produced many exciting designs for the lustre pottery which were made at Pilkington’s.

His designs were influenced by Persian, Spanish and Grecian designs, which can clearly be seen in his work.

He left in 1916 to do service in the Royal Flying corps and returned after the war in 1919 for a year leaving Pilkington’s in 1920.

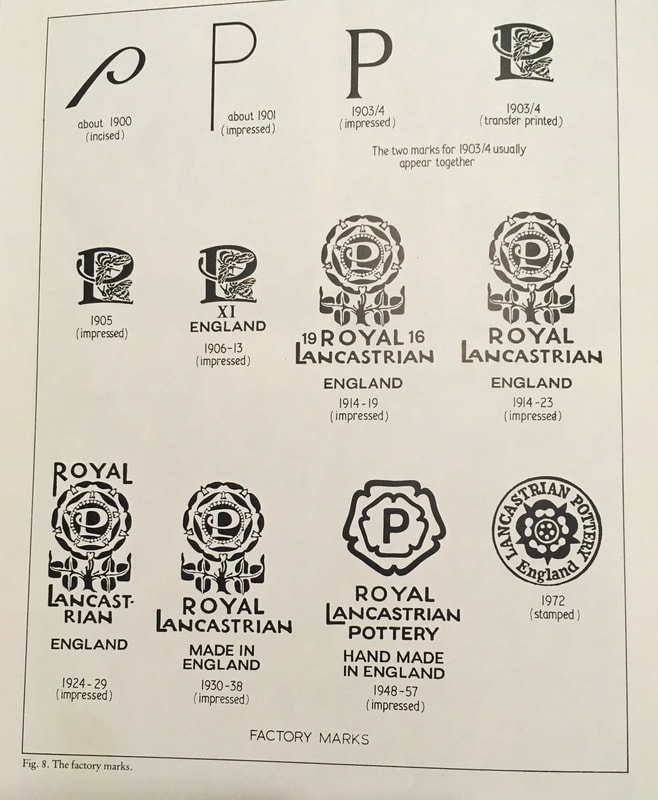

Lancastrian Pottery became Royal Lancastrian Pottery in 1913

King George V granted Lancastrian Pottery with a Royal Warrant in 1913, after visited Lord Derby and admiring his several Lancastrian vases which were proudly on display.

Lancastrian pottery was renamed Royal Lancastrian pottery. The trademark developed into a P surrounded by a Lancashire rose and the words Royal Lancastrian Pottery.

King George V granted Lancastrian Pottery with a Royal Warrant in 1913, after visited Lord Derby and admiring his several Lancastrian vases which were proudly on display.

Lancastrian pottery was renamed Royal Lancastrian pottery. The trademark developed into a P surrounded by a Lancashire rose and the words Royal Lancastrian Pottery.

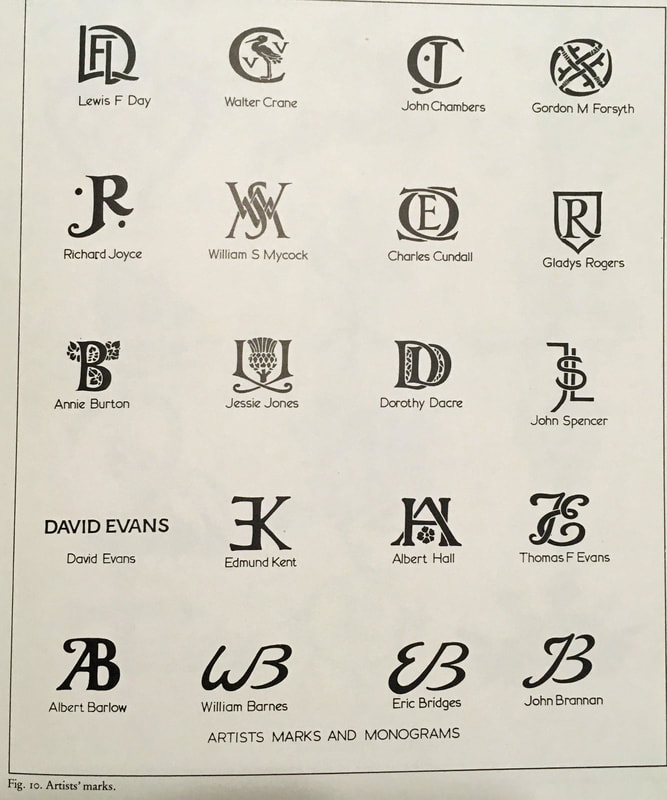

You can see how the marks in the pottery changed over the years. The P was for Pilkington's the L from 1903 for Lancastrian, whilst the two bees were for the Burton brothers.

The base of the pottery would be marked with the factory stamp, the artists stamp and the throwers stamp, as well as a number for the pot design. Each pot was given a unique design number and date for the year. Artists also used a drawing of their own design instead of numbers.

Pilkington’s became one of the most important international suppliers of high quality decorative tiles and art pottery. Supplying well-known china & glass shops worldwide.

They recruited a highly skilled team of artists, designers, chemists and craftsmen some drafted in from other famous potteries.

In 1915 some of the artist and workers left to go to war, there was no new designs made on the pottery for the next 12 years.

The base of the pottery would be marked with the factory stamp, the artists stamp and the throwers stamp, as well as a number for the pot design. Each pot was given a unique design number and date for the year. Artists also used a drawing of their own design instead of numbers.

Pilkington’s became one of the most important international suppliers of high quality decorative tiles and art pottery. Supplying well-known china & glass shops worldwide.

They recruited a highly skilled team of artists, designers, chemists and craftsmen some drafted in from other famous potteries.

In 1915 some of the artist and workers left to go to war, there was no new designs made on the pottery for the next 12 years.

Lustre ware & Iridescent lustre ware

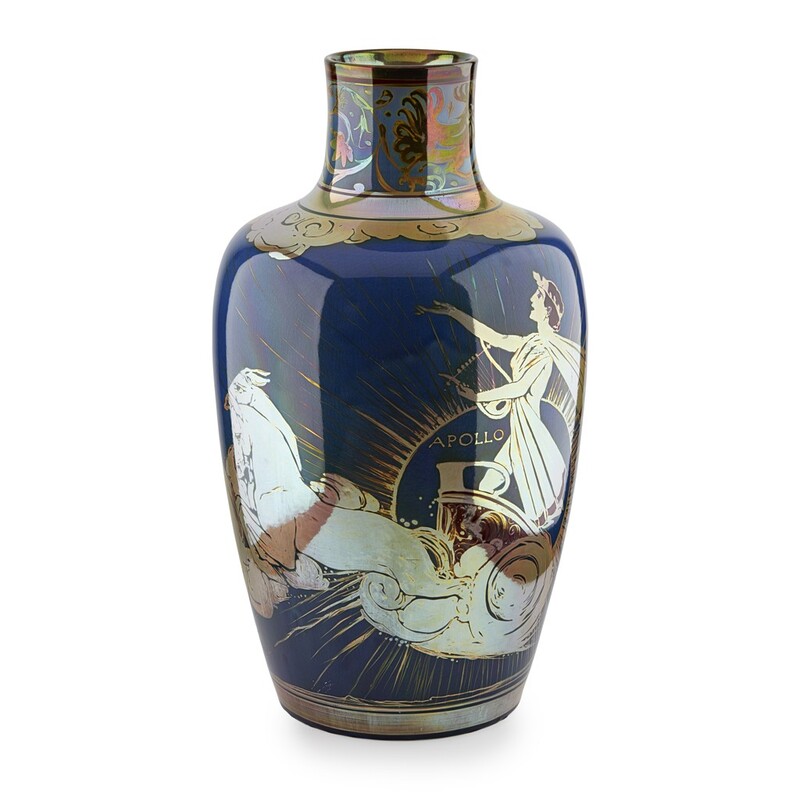

Royal Lancastrian Pottery soon became well known for its lustre glazes, which William Burton and his brother Joseph, developed. These designs and glazes were influenced by the early Islamic, Greek and Italian potters.

Iridescent lustre ware is pottery painted with gold, copper, or silver lustre.

Here are some examples of the Lustre ware they made.

Royal Lancastrian Pottery soon became well known for its lustre glazes, which William Burton and his brother Joseph, developed. These designs and glazes were influenced by the early Islamic, Greek and Italian potters.

Iridescent lustre ware is pottery painted with gold, copper, or silver lustre.

Here are some examples of the Lustre ware they made.

Not many pottery animals were made by the company, so they are very rare.

Some examples of Lustre Ware on display at Salford Art Gallery

Some examples of Lustre Ware on display at Salford Art Gallery

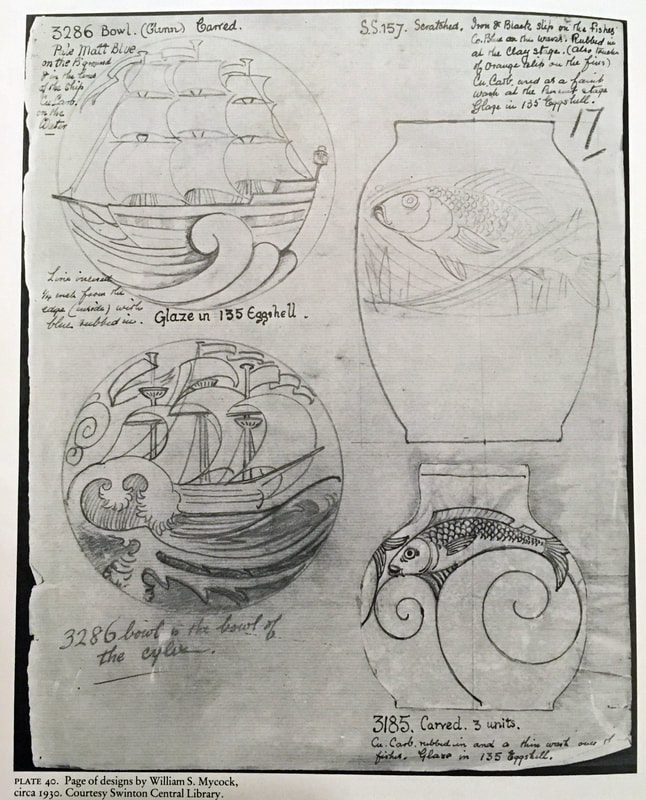

William Salter Mycock was born 1872

William joined Pilkington's in 1893.

He lived at 642 Wardley Lane, Swinton during 1911

He became a member of the labour party and elected councillor in 1919 he was chairman of the council in 1925 and was made an alderman in 1934. He became Mayor in 1937 and the first and only freeman of the borough of Swinton and Pendlebury in 1949. He died at his home in Blantyre Street, Swinton in 1950.

William joined Pilkington's in 1893.

He lived at 642 Wardley Lane, Swinton during 1911

He became a member of the labour party and elected councillor in 1919 he was chairman of the council in 1925 and was made an alderman in 1934. He became Mayor in 1937 and the first and only freeman of the borough of Swinton and Pendlebury in 1949. He died at his home in Blantyre Street, Swinton in 1950.

Other new glazes were introduced such as orange, vermillion, uranium orange and ultramarine

Then came Lapis ware

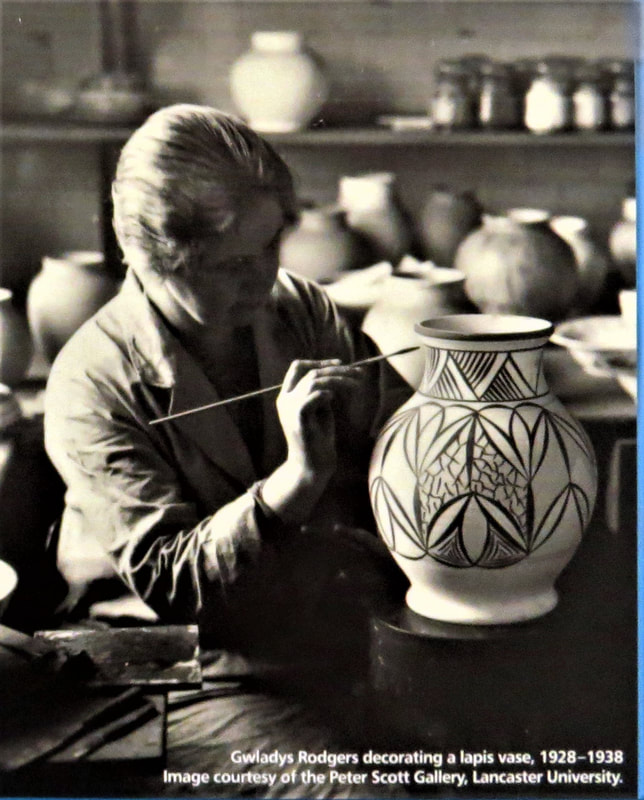

Lapis ware was developed in 1928 when a new chemist designed the merging of matt glaze and paint. They called it Lapis ware, as it resembled the mineral Lapis lazuli.

Mostly painted by Gwladys Rodgers and thrown by Edward T. Radford.

Lapis ware was developed in 1928 when a new chemist designed the merging of matt glaze and paint. They called it Lapis ware, as it resembled the mineral Lapis lazuli.

Mostly painted by Gwladys Rodgers and thrown by Edward T. Radford.

Gwladys Rodgers was born 1888 she joined Pilkington’s about 1907 she was one of the most well-known female artists. She painted lustre ware as well as Lapis ware. She lived in Campbell Road, Swinton.

In 1931 the company suffered a blow with the death of Richard Joyce, who was probably one of the best artists they had. Things stated to slow down because of the Great Depression in the 30’s.

In 1938 Royal Lancastrian Pottery stopped producing decorative art pottery wares because of falling sales, but tile production continued.

In 1938 Royal Lancastrian Pottery stopped producing decorative art pottery wares because of falling sales, but tile production continued.

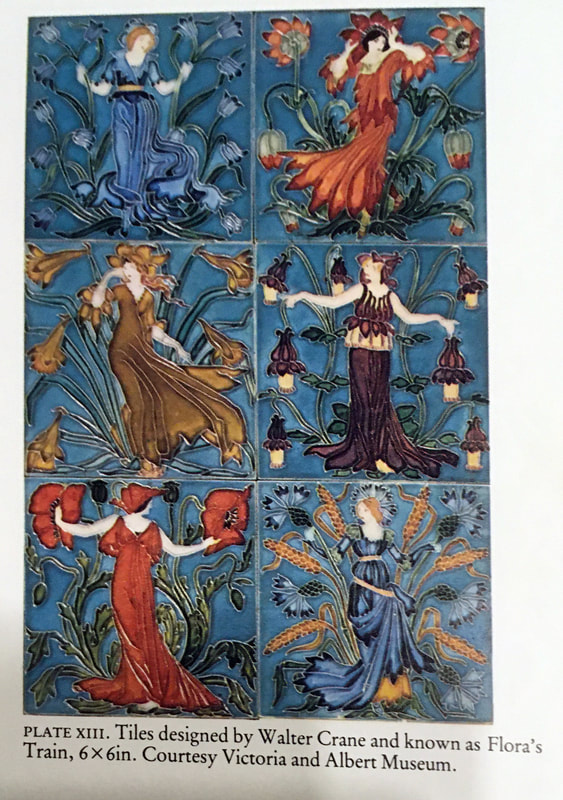

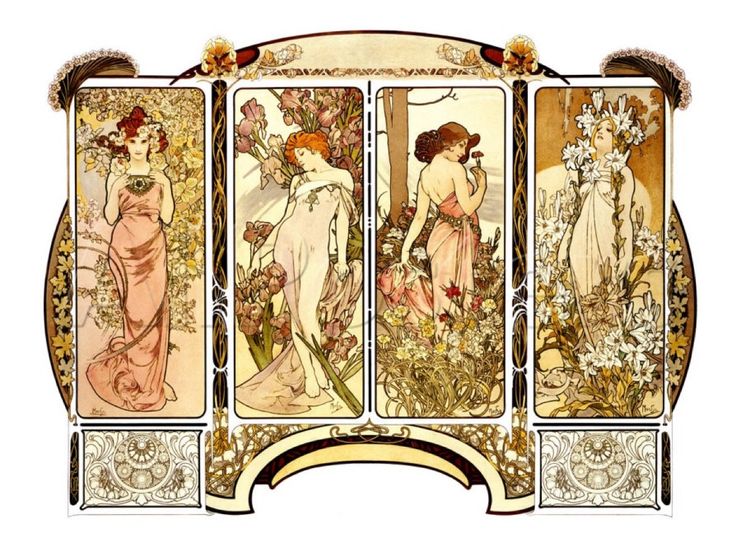

This is a beautiful example of tiles Les Fleurs made by Pilkington's designed by Alponse Mucha in watercolour in 1898.

Alponse Mucha was a Czech painter, illustrator and graphic artist, living in Paris during the Art Nouveau period.

A set of these tiles decorated the hall way of the Pilkington factory until the 1940's when the factory was redesigned.

Alponse Mucha was a Czech painter, illustrator and graphic artist, living in Paris during the Art Nouveau period.

A set of these tiles decorated the hall way of the Pilkington factory until the 1940's when the factory was redesigned.

Production of pottery restarted in 1948 and lasted until 1957/8.

An attempt to re-establish Royal Lancastrian Pottery was made in Blackpool in 1973 but was unsuccessful.

Pilkington’s Tiles Ltd continued making tiles and changed hands in 2004 to a private consortium. Finally Pilkington’s Tiles Ltd closed in 2010.

There is an excellent exhibition of Royal Lancastrian Pottery and history of Pilkington’s at Salford Art Gallery.

An attempt to re-establish Royal Lancastrian Pottery was made in Blackpool in 1973 but was unsuccessful.

Pilkington’s Tiles Ltd continued making tiles and changed hands in 2004 to a private consortium. Finally Pilkington’s Tiles Ltd closed in 2010.

There is an excellent exhibition of Royal Lancastrian Pottery and history of Pilkington’s at Salford Art Gallery.

thewallworks.weebly.com

Contact Wallwork History

Research and written content © Wallwork History

Images Salford Local History Library & Wallwork History

Contact Wallwork History

Research and written content © Wallwork History

Images Salford Local History Library & Wallwork History